Phosphatic Automation Plant

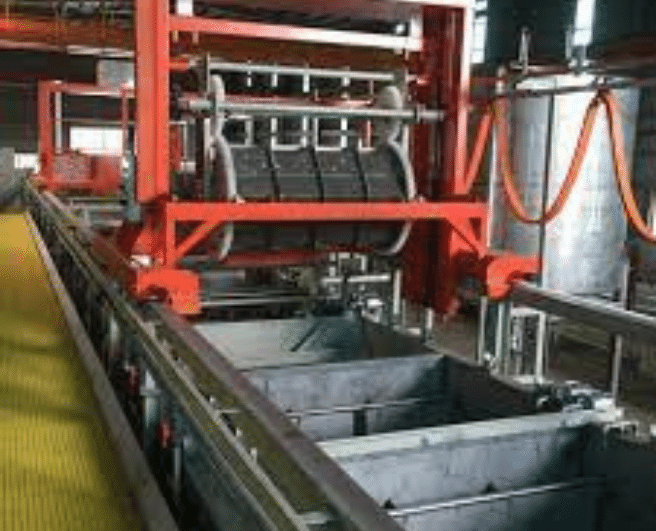

Phosphatic Automation Plant Bot Machine by SPT

SPT has introduced a groundbreaking automation plan for phosphatic processes, revolutionizing the way these operations are conducted. This comprehensive automation strategy optimizes efficiency, precision, and safety in phosphatic manufacturing. The plan integrates state-of-the-art technologies to streamline processes and enhance overall productivity.

Automated Mixing and Blending

SPT's automation plan incorporates advanced systems for the precise mixing and blending of phosphatic compounds. This ensures uniformity and accuracy in the composition of products, contributing to higher quality standards.

Process Monitoring and Control:

Our automation solution includes real-time monitoring and control systems that provide a continuous overview of the phosphatic manufacturing process. This allows for immediate intervention in case of deviations, ensuring that the final products consistently meet specifications.

Robotics in Material Handling:

The plan utilizes robotic systems for efficient material handling throughout the production line. This not only minimizes manual labor but also reduces the risk of human error, resulting in a more reliable and safer production environment.

Quality Assurance Sensors:

ntegration of advanced sensors guarantees rigorous quality control. These sensors detect and address any anomalies in the phosphatic production process, ensuring that only products meeting the highest standards are released to the market.

Energy Efficiency Measures:

SPT's automation plan prioritizes energy efficiency by implementing intelligent systems that optimize energy consumption during phosphatic manufacturing. This aligns with our commitment to sustainability and environmental responsibility.

Configuration

Centralized Control System

A centralized control hub manages and oversees the entire phosphatic manufacturing process, ensuring seamless communication and coordination between different automated units.

SCADA (Supervisory Control and Data Acquisition) Systems:

SCADA systems are implemented for real-time monitoring, data acquisition, and process visualization. This technology enhances overall control and responsiveness.

PLC (Programmable Logic Controller) Integration:

PLCs are strategically integrated into various stages of the phosphatic manufacturing process to control machinery and execute programmed tasks with precision.

Human-Machine Interface (HMI):

User-friendly HMI interfaces are employed to facilitate user interaction with the automated systems, allowing for easy monitoring, adjustment, and intervention when necessary.

Cloud-Based Data Storage:

The configuration includes cloud-based data storage for comprehensive data analysis, historical records, and performance optimization. This allows for remote access to critical information and facilitates data-driven decision-making.